| 99% |

With potassium carbonate; In acetonitrile; at 90℃; |

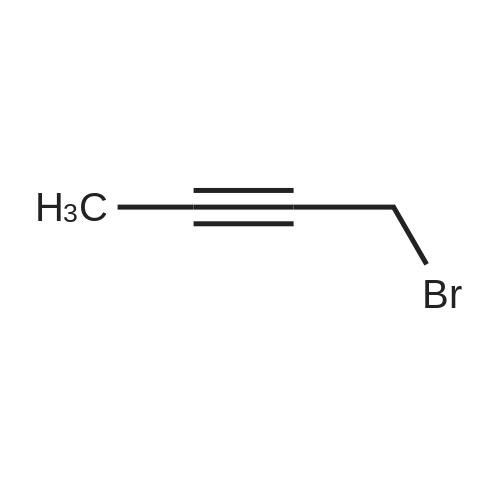

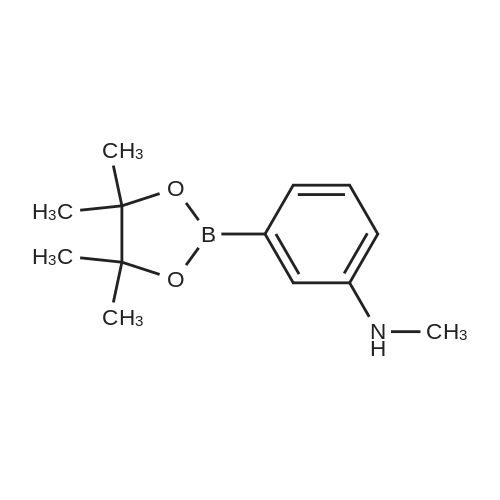

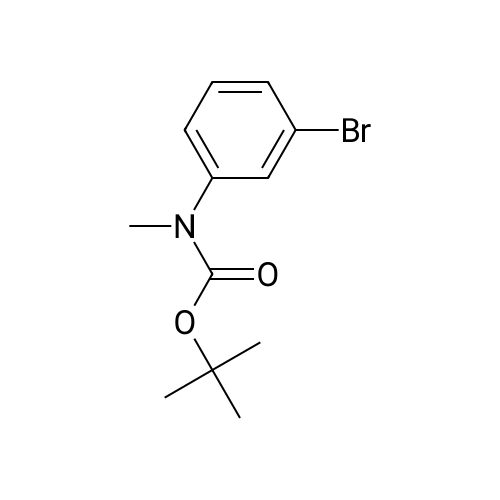

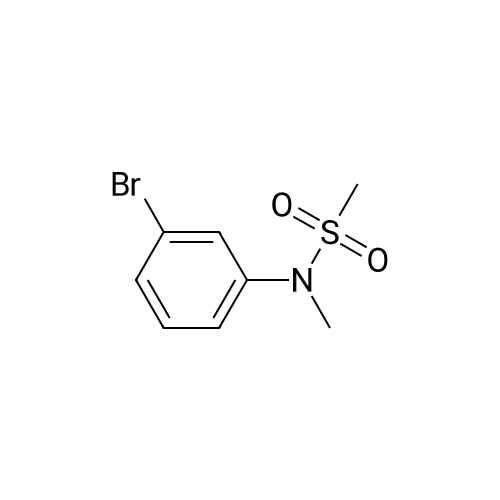

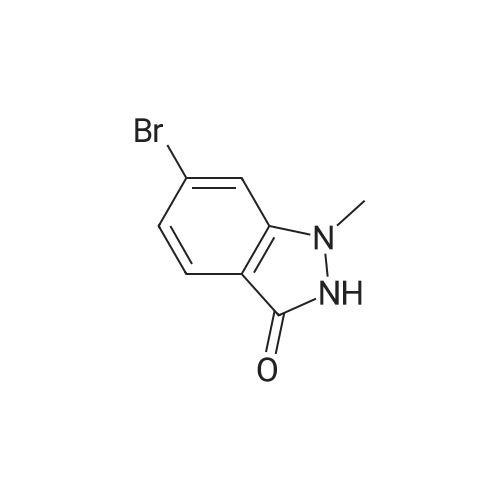

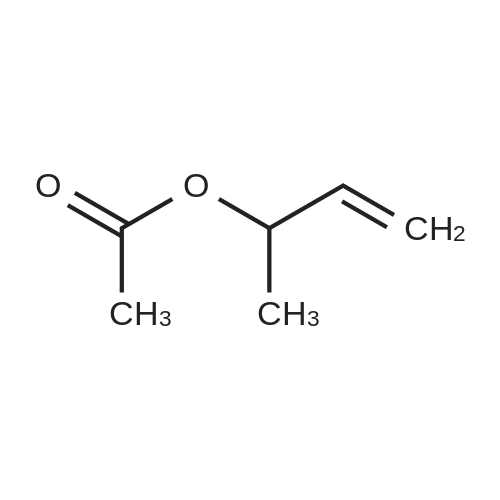

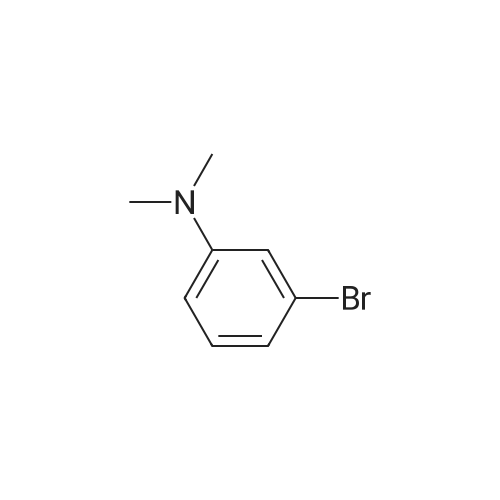

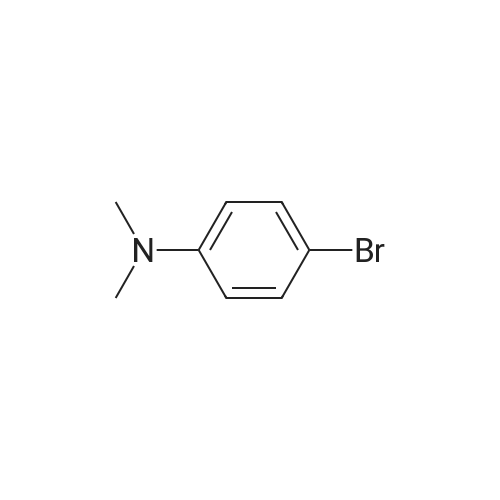

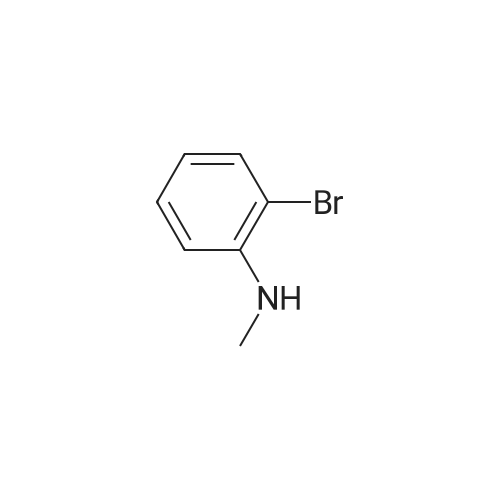

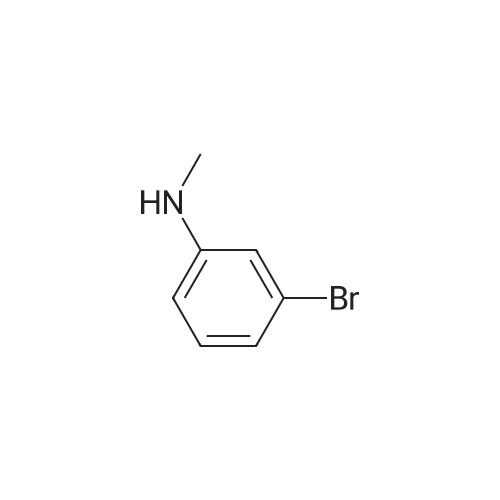

Compound 6 was synthesized in accordance with the following scheme. Potassium carbonate (7.46 g, 54.0 mmol, 2.0 eq.) was suspended in acetonitrile (20 mE), 3-bromo-N-methyl- aniline (4.96 g, 26.7 mmol, 1 eq.) and allyl bromide (3.87 g, 31.3 mmol, 1.2 eq.) were added, and the mixture was heated and refluxed overnight at 90 C. while being stirred. The reaction mixture was filtered through celite, the filtration residue and celite were then washed using ethyl acetate, and the solvent was removed under reduced pressure from a mixture of filtrate and washing solution. The resulting residue was purified by medium-pressure silica gel chromatography (eluent n-hexane/ethyl acetate=100/0 to 98/2) toobtain the objective compound 6 (5.98 g, 99%). 1H NMR (400 MHz, CDCl3): δ 2.95 (s, 3H),3.91-3.93 (m, 2H), 5.15-5.21 (m, 2H), 5.79-5.89 (m, 1H),6.63-6.65 (m, 1H), 6.82-6.86 (m, 2H), 7.06-7.10 (m, 1H); 13C NMR (100 MHz, CDCl3): δ 38.1, 55.0, 110.9, 115.0,116.4, 119.1, 123.5, 130.4, 133.1, 150.7; HRMS (ESIj:Calcd for [M+H], 226.02259, Found, 226.02210 (-0.5 mmu). |

| 73% |

With potassium carbonate; In acetonitrile; at 80℃; |

<strong>[66584-32-5]N-methyl-3-bromoaniline</strong> (2.27 g, 12.2 mmol), K2CO3 (4.20 g, 30.4 mol), and allyl bromide (4.00 g, 33.1 mmol) were dissolved in MeCN (50 mL) and stirred overnight at 80 C. After cooling to room temperature and filtering, the solvent of the filtrate was removed under reduced pressure. The remaining oil droplets were purified by silica gel column chromatography (CH2Cl2/n-hexane=), and N-allyl-<strong>[66584-32-5]N-methyl-3-bromoaniline</strong> was obtained (2.02 g, 8.94 mol, yield 73%). (0243) 1H NMR (300 MHz, CDCl3): δ=2.93 (s, 3H), 3.89-3.91 (m, 2H), 5.10-5.18 (m, 2H), 5.74-5.87 (m, 1H), 6.60 (dd, J=8.4 Hz, 2.6 Hz, 1H), 6.78-6.81 (m 2H), 7.05 (m, 1H). 13C NMR (100 MHz, CDCl3): δ=38.1, 55.1, 110.9, 115.0, 116.5, 119.1, 123.5, 130.4, 133.1, 150.7 |

| 72% |

With sodium carbonate; In tetrahydrofuran;Reflux; |

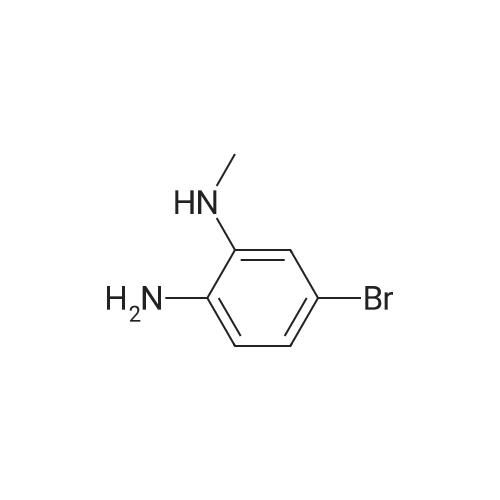

[Synthesis of Compound J5] (0194) Compound J4 (5.00 g, 26.9 mmol, 1 Eq) was dissolved in tetrahydrofuran (50 mL). Next, sodium carbonate (7.85 g, 56.9 mmol, 2.1 Eq) and allyl bromide (3.5 mL, 40.3 mmol, 1.5 Eq) were added and heated and refluxed overnight. More allyl bromide (3.5 mL, 40.3 mmol, 1.5 Eq) was added and heated and refluxed for two days. After air-cooling, the reaction solution was separated by filtration, and the filtrate was concentrated. The residue obtained was separated and purified by silica gel column chromatography (eluent: hexane/ethyl acetate=100/0 to 90/10), and compound J5 (5.53 g, 72%) was obtained as a colorless, transparent liquid. (0195) 1H NMR (CDCl3): δ 7.05 (t, J=8.1 Hz, 1H), 6.83-6.79 (m, 2H), 6.61 (dd, J=8.4 Hz, 2.2 Hz, 1H), 5.81 (ddt, J=17.0 Hz, 10.4 Hz, 4.9 Hz, 1H), 5.16 (dq, J=10.4 Hz, 1.6 Hz, 1H), 5.14 (dq, J=17.0 Hz, 1.6 Hz, 1H), 3.90 (dt, J=4.9 Hz, 1.6 Hz, 2H), 2.93 (s, 3H).; 13C NMR (CDCl3): δ 150.7 (C), 133.1 (CH), 130.4 (CH), 123.5 (C), 119.1 (CH), 116.5 (CH2), 115.1 (CH), 111.0 (CH), 55.1 (CH2), 38.2 (CH2); HRMS-ESI (m/z): [M+H]+ calcd for C10H13NBrN: 226.02259. found: 226.02478 (-2.2 mDa, -9.7 ppm). |

Chemistry

Chemistry

Pharmaceutical Intermediates

Pharmaceutical Intermediates

Inhibitors/Agonists

Inhibitors/Agonists

Material Science

Material Science

For Research Only

For Research Only

110K+ Compounds

110K+ Compounds

Competitive Price

Competitive Price

1-2 Day Shipping

1-2 Day Shipping